The requirements of the Building Regulations and practical advice in Approved Document L include provision for insulation to some ground floors. The requirement is that ground floors should have a maximum insulation value (U value) of 0.45 W/m2K. Some {ground floor} slabs that are larger than 10 m in both length and breadth may not need the addition of an insulating layer to provide the U value of 0.45.

Of the heat that is transferred through a solid, ground supported floor a significant part of the transfer occurs around the perimeter of the floor to the ground below, foundation walls and ground around the edges of the floor, so that the cost of insulating the whole floor is seldom justified. Insulation around or under the edges of a solid floor will significantly reduce heat losses to the extent that overall insulation is unnecessary.

In the CIBS guide to the thermal properties of building structures, the U value of an uninsulated solid floor 20 x 20 m on plan, with four edges exposed, is given as 0.36 W/m2K and one 10 x 10 m as 0.6W/m2K. The 20 x 20 floor has a U value below that in the requirement of the Building Regulations and will not require insulation. The U value of a 10 m2 floor can be reduced by the use of edge insulation. With edge insulation of a metre deep all around and under the floor, the U value can be reduced to 0.48W/m2K which is somewhat higher than the U value in the requirement of the Building Regulations and may necessitate some small overall insulation. This is the basis for the assumption that floor slabs that are larger than 10 m in both length and width may not need an overall insulation layer.

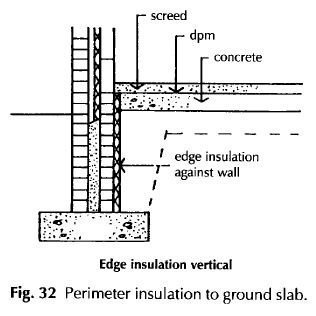

To reduce heat losses through thermal bridges around the edges of solid floors that do not need overall insulation, and so minimise problems of condensation and mould growth, it may be wise to build in edge insulation, particularly where the wall insulation is not carried down below the ground floor slab. Edge insulation is formed either as a vertical strip between the edge of the slab and the wall or under the slab around the edges of the floor as illustrated in Fig. 32. The depth or width of the strips of insulation vary from 0.25 m to 1 m and the thickness of the insulation will be similar to that needed for overall insulation.

The only practical way of improving the insulation of a solid ground floor to the required U value is to add a layer of some material with a high insulation value to the floor. The layer of insulation may be laid below a chipboard or plywood panel floor finish or below a timber boarded finish or below the screed finish to a floor or under the concrete floor slab. With insulation under the screed or slab it is important that the density of the insulation board is sufficient to support the load of the floor itself and imposed loads on the floor. A density of at least 16kg/m3 is recommended for domestic buildings.

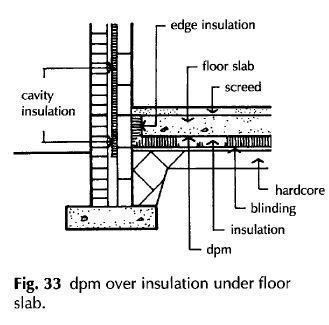

The advantage of laying the insulation below the floor slab is that the high density slab, which warms and cools slowly (slow thermal response) in response to changes in temperature of the constant low output heating systems, will not lose heat to the ground. The damp-proof membrane may be laid under or over the insulation layer or under the floor screed. The {damp-proof membrane} should be under insulation that absorbs water and may be over insulation with low water absorption and high resistance to ground contaminants.

With the insulation layer and the dpm below the concrete

floor slab it is necessary to continue the dpm and insulation up vertically around the {edges} of the slab to unite with the dpc in {wall}s as illustrated in Fig. 33.

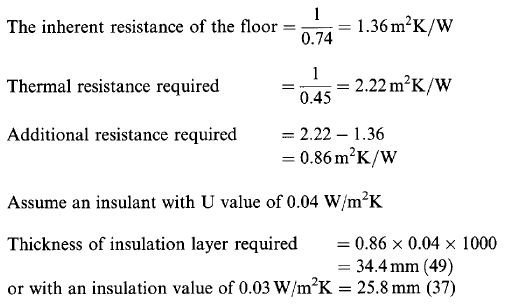

One method of determining the required thickness of insulation is to use a thickness of insulation related to the U value of the chosen insulation material, as for example thicknesses of 25 mm for a U value of 0.02W/m2K, 37 mm for 0.03 W/m2K, 49 mm for 0.04W/m2K and 60 mm for 0.05 W/m2K, ignoring the inherent resistance of the floor.

Another more exacting method is to calculate the required thickness related to the actual size of the floor and its uninsulated U value, taken from a table in the CIBS guide to the thermal properties of building structures. For example, from the CIBS table the U value of a solid floor 10 x 6 m, with four edges exposed is 0.74W/m2K.

These thicknesses are appreciably less than those given by the first method, shown in brackets.

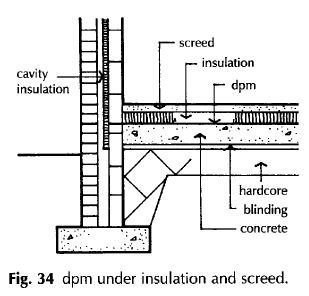

Where the wall insulation is in the cavity or on the inside face of the wall it is necessary to avoid a cold bridge across the foundation wall and the edges of the slab, by fitting insulation around the edges of the slab or by continuing the insulation down inside the cavity, as illustrated in Fig. 34.

An advantage of fitting the dpm above the insulation is that it can be used to secure the upstand edge insulation in place while concrete is being placed.

The disadvantage of the dpm being below the concrete floor slab is that it will prevent the wet concrete drying out below and so lengthen the time required for it to adequately dry out, to up to 6 months. A {concrete} floor slab that has not been sufficiently dried out may adversely affect water sensitive floor finishes such as {wood}.

The advantage of laying the insulation layer under the screed is that it can be laid inside a sheltered building on a dried slab after the roof is finished and that the dpm, whether over or under the insulation layer, can more readily be joined to the dpc in walls, as illustrated in Fig. 34. Where the wall insulation is in the cavity it should be continued down below the floor slab to minimise the cold bridge across the wall to the screed as illustrated in Fig. 34.

If the dpm is laid below the insulation it is necessary to spread a separating layer over the insulation to prevent wet screed running into the joints between the insulation boards. The separating layer should be building paper or 500 gauge polythene sheet.

To avoid damage to the insulation layer and the dpm it is necessary to take care in tipping, spreading and compacting wet concrete or screed. Scaffold boards should be used for harrowing and tipping concrete and screed and a light mesh of chicken wire can be used over separating layers or dpms over insulation under screeds as added protection.