These are bricks which are sufficiently hard to safely carry the loads

normally supported by brickwork, but because they have a dull texture or poor colour they are not in demand for use as facing bricks

which show on the outside when built and affect the appearance of buildings. These ‘common’ bricks are used for internal walls and for rear walls which are not usually exposed to view. Any brick which is sufficiently hard and of reasonably good shape and of moderate price may be used as a ‘common’ brick. The type of brick most used as a common brick is the Fletton brick.

Facings

This is by far the widest range of bricks as it includes any brick which

is sufficiently hard burned to carry normal loads, is capable of withstanding the effects of rain, wind, soot and frost without breaking up and which is thought to have a pleasant appearance. As there are as many different ideas of what is a pleasant looking brick as there are bricks produced, this is a somewhat vague classification.

Engineering bricks

These are bricks which have been made from selected clay, which have been carefully prepared by crushing, have been very heavily moulded and carefully burned so that the finished brick is very solid and hard and is capable of safely carrying much heavier loads than other types of brick. These bricks are mainly used for walls carrying exceptionally heavy loads, for brick piers and general engineering works. The two best known engineering bricks are the red Southwater brick and the blue Staffordshire brick. Both are very hard, dense and do not readily absorb water. The ultimate crushing resistance of engineering bricks is greater than 50 N/mm2.

Semi-engineering bricks

These are bricks which, whilst harder than most ordinary bricks, are not so hard as engineering bricks. It is a very vague classification without much meaning, more particularly as a so-called semi-engineering brick is not necessarily half the price of an engineering {brick}.

Composition of clay

Clays suitable for brick making are composed mainly of silica in the form of grains of sand and alumina, which is the soft plastic part of clay which readily absorbs water and makes the clay plastic and which melts when burned. Present in all clays are materials other than the two mentioned above such as lime, iron, manganese, sulphur and phosphates. The proportions of these materials vary widely and the following is a description of the composition, nature and uses of some of the most commonly used bricks classified according to the types of clay from which they are produced.

Flettons

There are extensive areas of what is known as Oxford clay. The clay is

composed of just under half silica, or sand, about one-sixth alumina, one-tenth lime and small measures of other materials such as iron, potash and sulphur. The clay lies in thick beds which are economical to excavate. In the clay, in its natural state, is a small amount of mineral oil which, when the bricks are burned, ignites and assists in the burning.

Because there are extensive thick beds of the clay, which are economical to excavate, and because it contains some oil, the cheapest of all clay bricks can be produced from it. The name Fletton given to these bricks derives from the name of a suburb of Peterborough around which the clay is extensively dug for brickmaking. Flettons are cheap and many hundreds of millions of them are used in building every year. The bricks are machine moulded and burned and the finished brick is uniform in shape with sharp square edges or arises. The bricks are dense and hard and have moderately good strength; the average pressure at which these bricks fail, that is crumble, is around 21 N/mm2

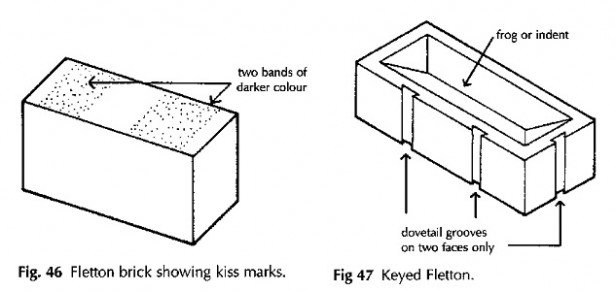

The bricks are light creamy pink to dull red in colour and because of the smooth face of the brick what are known as ‘kiss marks’ are quite distinct on the long faces. These ‘kiss marks’ take the form of three different colours, as illustrated in Fig. 46.

The surface is quit

e hard and smooth and if the brick is to be used for wall surfaces to be plastered, two faces are usually indented with grooves to give the surface a better grip or key for plaster. The bricks are then described as ‘keyed Flettons’. Figure 47 is an illustration of a keyed Fletton.

Marls

By origin the word marl denotes a clay containing a high proportion

of lime (calcium carbonate), but by usage the word marl is taken to denote any sandy clay. This derives from the use of sandy clays, containing some lime, as a top dressing to some soils to increase fertility. In most of the counties of England there are sandy clays, known today as marls, which are suitable for brick making. Most of the marl clays used for brick making contain little or no lime. Many of the popular facing bricks produced in the Midlands are made from this type of clay and they have a good shape, a rough sandy finish and vary in colour from a very light pink to dark mottled red.

Gaults

The gault clay does in fact contain a high proportion of lime and the

burned brick is usually white or pale pink in colour. These bricks are of good shape and texture and make good facing bricks, and are more than averagely strong. The gault clay beds are not extensive in this country and lie around limestone and chalk hills in Sussex and Hampshire.

Clay shale bricks

Some clay beds have been so heavily compressed over the centuries by the weight of earth above them that the clay in its natural state is quite firm and has a compressed flaky nature. In the coal mining districts of this country a considerable quantity of clay shale has to be dug out to reach coal seams and in those districts the extracted shale is used extensively for brick making. The bricks produced from this shale are usually uniform in shape with smooth faces and the bricks are hard and durable. The colour of the bricks is usually dull buff, grey, brown or red. These bricks are used as facings, commons and semi-engineering, depending on their quality.

Calcium Silicate bricks

Calcium silicate bricks are generally known as sand-lime bricks. The

output of these bricks has increased over the past few years, principally because the output of Fletton bricks could not keep pace with the demand for a cheap common brick and sand-lime bricks have been mainly used as commons. The bricks are made from a carefully controlled mixture of clean sand and hydrated lime which is mixed together with water, heavily moulded to brick shape and then the moulded brick is hardened in a steam oven. The resulting bricks are very uniform in shape and colour and are normally a dull white. Coloured sand-lime bricks are made by adding a colouring matter during manufacture. These bricks are somewhat more expensive than Flettons and because of their uniformity in shape and colour they are not generally thought of as being a good facing brick. The advantage of them however is that the material from which they are made can be carefully selected and accurately proportioned to ensure a uniform hardness, shape and durability quite impossible with the clay used for most bricks.

See:

{Flint-lime bricks}

{Special bricks}